Services

Cleanroom Facility Planning and Design

Planning and design for ISO-certified cleanroom facilities including Architectural cleanroom walls, doors, ceiling, flooring, furniture, and special use wet process and fume hood workstation systems along with engineering of Mechanical/Electrical/Plumbing (MEP) support systems for recirculation air-handling units, make-up air, exhaust air, plumbing, process piping, electrical power and lighting distribution, hazardous production material (HPM) delivery, Hazardous Gas Monitoring Systems (HGMS), controls, and telecommunications.

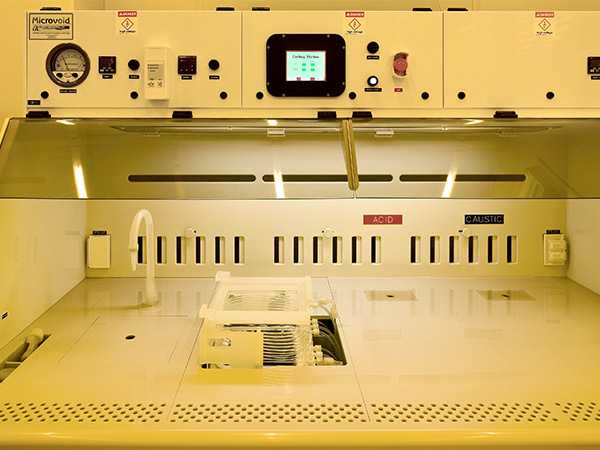

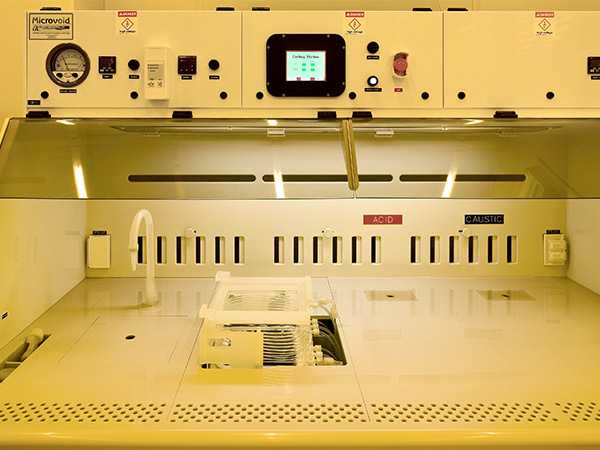

Wet Process and Fume Hood Workstation

Design of specialized custom wet process and fume hoods for clean processes including etching, solvent cleaning, resist coating and developing, and other custom processes. We assist project stakeholders and user groups in developing the unique processes and features each bench/hood will support, along with requirements for materials of hood construction to meet chemical resistance, longevity, and regulatory requirements such as Factory Mutual (FM) and Underwriters Laboratories (UL). Additional features and requirements are established for cleanliness classification (HEPA laminar flow, exhaust only); piped and electrical utilities; process equipment such as spinners, bake modules, ambient and heated chemical baths, quick dump and cascade rinse tanks; general use and cup sinks; material storage systems; and waste collection systems such as fixed and mobile carboy storage containers.

Trace Metals Analysis Laboratories

Planning and design for specialized Trace Metals Analysis (TMA) laboratories facilities for isotope geochemistry for determinization of major, minor, and trace element concentrations down to part per trillion (and beyond) levels along with high-precision isotopic measurements of metals. Design of these unique facilities include metal-free ISO-certified cleanroom spaces for process bays, weight/balance, gowning, and circulation along with equipment and laboratory spaces for mass spectrometry instrumentation and other analytical processes. Design also includes specialized fume hoods and laminar flow clean benches with metal-free design (no exposed metal) for Trace Metals Analysis for use with sample preparation, acid distillation purification systems, and hotplate evaporation.

Services

Cleanroom Facility Planning and Design

Planning and design for ISO-certified cleanroom facilities including Architectural cleanroom walls, doors, ceiling, flooring, furniture, and special use wet process and fume hood workstation systems along with engineering of Mechanical/Electrical/Plumbing (MEP) support systems for recirculation air-handling units, make-up air, exhaust air, plumbing, process piping, electrical power and lighting distribution, hazardous production material (HPM) delivery, Hazardous Gas Monitoring Systems (HGMS), controls, and telecommunications.

Wet Process and Fume Hood Workstation

Design of specialized custom wet process and fume hoods for clean processes including etching, solvent cleaning, resist coating and developing, and other custom processes. We assist project stakeholders and user groups in developing the unique processes and features each bench/hood will support, along with requirements for materials of hood construction to meet chemical resistance, longevity, and regulatory requirements such as Factory Mutual (FM) and Underwriters Laboratories (UL). Additional features and requirements are established for cleanliness classification (HEPA laminar flow, exhaust only); piped and electrical utilities; process equipment such as spinners, bake modules, ambient and heated chemical baths, quick dump and cascade rinse tanks; general use and cup sinks; material storage systems; and waste collection systems such as fixed and mobile carboy storage containers.

Trace Metals Analysis Laboratories

Planning and design for specialized Trace Metals Analysis (TMA) laboratories facilities for isotope geochemistry for determinization of major, minor, and trace element concentrations down to part per trillion (and beyond) levels along with high-precision isotopic measurements of metals. Design of these unique facilities include metal-free ISO-certified cleanroom spaces for process bays, weight/balance, gowning, and circulation along with equipment and laboratory spaces for mass spectrometry instrumentation and other analytical processes. Design also includes specialized fume hoods and laminar flow clean benches with metal-free design (no exposed metal) for Trace Metals Analysis for use with sample preparation, acid distillation purification systems, and hotplate evaporation.